Three Zone Split Tube Furnace (Cvd)

Three Zone Split Tube Furnace (Cvd) Specification

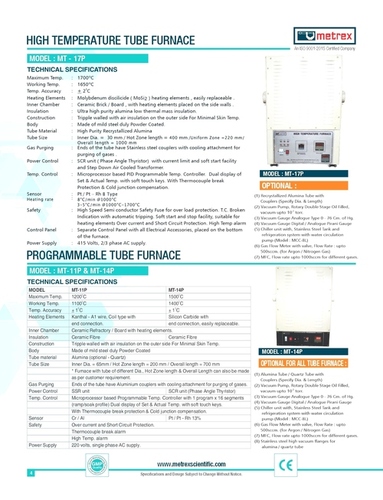

- Rating

- High temperature range up to 1200C

- Feature

- Three independently controlled temperature zones, rapid heating, computer connectivity, programmable temperature profiles, PID controller

- Condition

- New

- Type

- Split Tube Furnace (CVD)

- Usage

- Laboratory, Research, Material Processing

- Power

- 3.5 kW to 6 kW (depending on model)

- Voltage

- 220V/240V, 50-60 Hz

- Size

- Tube diameter options: 50mm, 60mm, 80mm, 100mm (customizable)

- Dimensions

- Furnace length: approx. 900mm-1200mm (exterior)

- Weight

- 56kg - 85kg (depending on model and tube size)

- Application

- Chemical Vapor Deposition, Thermal Treatment, Synthesis

- Fuel Type

- Electric

- Capacity

- Tube volume: 2L to 10L (depends on diameter and length)

About Three Zone Split Tube Furnace (Cvd)

- Number of zone :One/Two /Three Zone (as per user requirement)

- Heating temperature range : Upto1200 C/1400 C

- Heating Element: A-1/Silicon Carbide

- Temperature accuracy : +/-1 C

- Furnace tube size : ID = 60 mm /OD =65mm/ length= 1200 mm

- Quartz tube with couplers :High purity fused quartz

- Size:ID =60mm, OD=65mm,length=1200mm

- Heating rate : 15 C per Minute (max.) or user settable Each Hot Zone length : 200 mm length

- Display : 7 LCD Touch Screen HMI to control all vital operation of CVD i.e. temperature and gas flow. With Data logging of temperature and gas flow.

- Construction : Horizontal and split type

- Insulation : Vacuum formed Zirconia fiber

- Shell Construction : MS body fabricated from 20/18 gauge sheet, powder coated for superior finish. Double layer body for low surface temp.

- Temperature control : ( 1x16=16 segment) PID programmable Digital Temperature controller x 3 no. (separate for each zone)

- Temperature sensor : 3 numbers (k type-1200 C/R type-1400 C)

- Power control : Through the phase angle controlled SSRUnit/Thyristor Unit

Gas purging arrangement

- Digital vacuum gauge wih vacuum display upto 10-6 torr.

- Gas mixing chamber : One unit kept between the Rotameters and the furnace

- Furnace stand to height of 1 meter

OPTIONAL:-

- Chiller with Circulation Pump

- Gas Cylinder with Regulator

- Mass flow controller for different gases, flow rate upto 500 sccm or as required with digital display (Optional)

- Rotameter for different gases with needle valve.

- Centrifuges ystems

Versatile Three-Zone Temperature Control

Each temperature zone in this split tube furnace is independently managed using state-of-the-art PID controllers and a digital interface. This design guarantees precise temperature regulation, with an accuracy of 1C, across the entire heating chamber, enabling complex thermal profiles and gradients tailored for Chemical Vapor Deposition, material synthesis, and advanced research projects.

Superior Construction and Material Compatibility

The furnace is built to accommodate a range of tube materials, including quartz, alumina, and high-grade ceramics, enabling high-temperature processes up to 1200C or 1500C. With gas-tight sealing, it supports various atmospheresvacuum, inert, reducing, or oxidizingsuitable for demanding scientific and industrial applications while ensuring energy efficiency and repeatable results.

Enhanced Safety and Smart Features

Safety is integral to this furnaces design, featuring over-temperature protection, a door interlock switch, and an emergency shutoff. Users benefit from rapid heating and cooling, programmable ramp/soak profiles, and computer connectivity for data logging and remote control. These smart features optimize workflow and ensure safe, streamlined operation in any laboratory setting.

FAQs of Three Zone Split Tube Furnace (Cvd):

Q: How does the three-zone temperature control system benefit my laboratory processes?

A: The three-zone temperature control enables precise management of temperature gradients across your samples. With each zone independently regulated by a PID controller, you can set custom ramp/soak profilesideal for Chemical Vapor Deposition, material synthesis, and advanced thermal treatments that require nuanced heating protocols.Q: What materials are compatible with the furnace tubes and what applications does this support?

A: The furnace supports tubes made from quartz, alumina, and high-grade ceramics. This compatibility allows for a broad spectrum of applications, including chemical vapor deposition, thermal treatment, and synthesis, making it suitable for research institutions, industrial laboratories, and specialized manufacturing processes.Q: When should I use vacuum or controlled gas atmospheres with this split tube furnace?

A: Use vacuum or controlled gas atmospheres when working with processes requiring a specific environment, such as preventing contamination or achieving unique material characteristics. The gas-tight flanges and programmable controls support inert, reducing, or oxidizing conditions for optimal material outcomes during CVD or synthesis.Q: Where can I install or use the Three Zone Split Tube Furnace?

A: This furnace is designed for laboratory, research, and material processing settings. Its size, programmable features, and safety systems make it suitable for universities, research institutes, and industrial labs requiring high-temperature, controlled-environment processing.Q: What safety measures are incorporated in the furnace design?

A: The furnace includes multiple safety features such as over-temperature protection, a door interlock switch to prevent accidental opening during operation, and an emergency shutoff mechanism. These ensure user protection and equipment reliability.Q: How do I program temperature profiles and monitor the process?

A: You can set and monitor temperature profiles using the intuitive digital display interface. Programmable ramp/soak profiles, computer connectivity, and real-time readouts from K-type, N-type, or R-type thermocouples enable precise control and data logging throughout your experiment.Q: What is the advantage of the split tube and rapid cooling system?

A: The split tube design allows easy access to samples and facilitates rapid cooling. This reduces downtime between experiments, enables quicker sample handling, and helps maintain sample integrity by minimizing unwanted thermal effects after processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Furnace Products Category

High Temperature Furnace With Gas

Price 400000 INR / Number

Minimum Order Quantity : 1 Number

Dimensions : Customizable dimensions based on specifications

Weight : Dependent on model specifications

Size : Compact or large customizable as required

Condition : New

Low Energy Consuming High Temperature Tube Furnace

Price 3000000 INR / Number

Minimum Order Quantity : 1 Number

Dimensions : Depends on tube length and configuration

Weight : Varies by model (approx. 40 to 100 kg)

Size : Customizable tube diameter and length available

Condition : New

High Temperature Muffle Furnace-1500

Price 700000 INR / Number

Minimum Order Quantity : 1 Number

Dimensions : Varies based on model; Example External: 580 x 650 x 665 mm Internal: 150 x 150 x 350 mm (for 6 L)

Weight : Approx. 54 kg 132 kg (varies based on model)

Size : Various sizes based on given capacity

Condition : New

Tubular Furnace

Price 800000 INR / Number

Minimum Order Quantity : 1 Number

Dimensions : Custom sizes available (as per requirements)

Weight : Varies based on model.

Size : Varies based on model and user requirements.

Condition : New

Products Description

|

METREX SCIENTIFIC INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |