High Temperature Muffle Furnace-1500

High Temperature Muffle Furnace-1500 Specification

- Rating

- Designed for High Temperature Operations

- Feature

- High-Temperature Capability (up to 1500C) Silicon carbide heating elements Precise Control

- Condition

- New

- Type

- Muffle Furnace

- Usage

- Heat treatment Research Industrial processes

- Power

- 2.5 kW - 14.5 kW (varies based on model)

- Voltage

- 230 V / 415 V 50 Hz

- Size

- Various sizes based on given capacity

- Dimensions

- Varies based on model; Example - External: 580 x 650 x 665 mm Internal: 150 x 150 x 350 mm (for 6 L)

- Weight

- Approx. 54 kg - 132 kg (varies based on model)

- Application

- Laboratory and Industrial Applications

- Fuel Type

- Electric

- Capacity

- 6 L 13 L 55 L (varies based on model)

- Warranty

- 1 Year Manufacturer Warranty

About High Temperature Muffle Furnace-1500

The instrument maximum operating temperature of 1300 degree C.

The working operating temperature must be at least 1200 degree C.

The instrument up and away door type to keep hot face away from user.

The instrument temperature uniformity of 5 degree C for 60% of internal dimensions and 10 degree C for overall internal dimensions. Vendor must provide uniformity graph data sheet at 500 degree C, 900 degree C and 1200 degree

Advanced Heating Technology for Precision

Equipped with silicon carbide heating elements, the High Temperature Muffle Furnace-1500 delivers rapid and consistent heating, essential for precise thermal processes in laboratories and industrial environments. The advanced control systems guarantee repeatable results, making it ideal for research and quality assurance applications.

Versatile Designs for Varied Applications

Available in multiple capacities and flexible external/internal dimensions, this furnace meets the needs of different laboratory and industrial tasks. Its durable construction allows for safe handling of intense heat operations, such as metal annealing, ashing, and material testing.

Ease of Use and Reliable Performance

Simple electric operation at standard Indian voltages (230 V/415 V) makes integration seamless in various setups. Built-in safeguards and digital controls enable intuitive user operation while ensuring high reliability, making the furnace a favored choice among manufacturers, exporters, importers, and suppliers.

FAQs of High Temperature Muffle Furnace-1500:

Q: How is the temperature precisely controlled in the High Temperature Muffle Furnace-1500?

A: The furnace is equipped with advanced digital controllers that allow users to set and maintain temperatures up to 1500C accurately. Silicon carbide heating elements further ensure consistency and precise thermal management throughout the operation.Q: What types of heat treatment processes can this furnace be used for?

A: It is suitable for a range of processes, including annealing, ashing, material testing, and high-temperature research applications in laboratories and industrial facilities.Q: When should maintenance be performed for optimal performance?

A: Routine maintenance checks are recommended before each usage cycle and after extended operation periods. Regular inspection of heating elements, seals, and digital controls will ensure long-lasting performance and safety.Q: Where can the High Temperature Muffle Furnace-1500 be installed?

A: The furnace is designed for installation in laboratory, research, and industrial settings. Its compact, customizable dimensions and robust design allow for flexible positioning on workbenches or dedicated furnace areas.Q: What is the process for using this furnace for material testing?

A: Users first set the desired temperature via the digital controller, load the material inside the chamber, and initiate the heating cycle. The precise control technology ensures consistent results for various materials during high-temperature testing.Q: What benefits does this muffle furnace offer over conventional models?

A: Key benefits include high-temperature capability (up to 1500C), accurate digital controls, energy-efficient silicon carbide heating elements, a variety of capacities and safety features, making it more versatile and reliable than standard furnaces.Q: Who can benefit from using the High Temperature Muffle Furnace-1500?

A: Manufacturers, laboratories, research institutes, exporters, importers, and suppliers in India involved in heat treatment and material sciences will find this furnace advantageous for its robust performance and adaptability to numerous processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Furnace Products Category

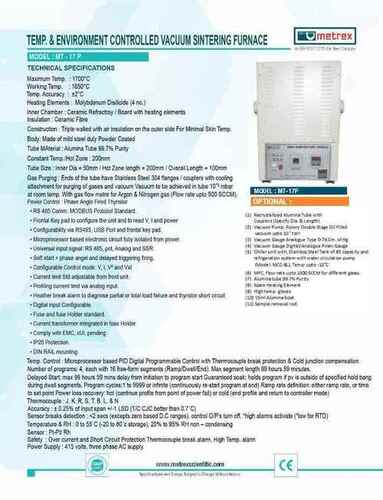

Temperature and Environment Controlled Vacuum Sintering Furnace

Type : Temperature and Environment Controlled Vacuum Sintering Furnace

Condition : New

Warranty : 12 months from the date of purchase

Feature : Environment controlled vacuum sintering programmable controller with temperature ramp feature

Usage : Other, Industrial sintering applications under controlled environment

Fuel Type : Electric

Three Zone Tube Furnace

Type : Three Zone Tube Furnace

Condition : New

Warranty : Manufacturer warranty included

Feature : Three independent heating zones

Usage : Heat treatment material testing sintering etc., Other

Fuel Type : Electric

Programmable Muffle Furnace - 1500 C

Type : Programmable Muffle Furnace

Condition : New

Warranty : 1 year manufacturer warranty

Feature : Programmable temperature setting up to 1500C

Usage : Other, Heating sintering and industrial applications

Fuel Type : Electric

High Temperature Muffle Furnace - 1400 C (Advance)

Type : Muffle Furnace

Condition : New

Warranty : Manufacturer warranty duration not specified

Feature : Advanced design; Hightemperature operation up to 1400C

Usage : Other, Laboratory industrial and research applications

Fuel Type : Electric

Products Description

|

METREX SCIENTIFIC INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |