Most Popular Products

High Temperature / Tube Furnace(Single Zone)

High Temperature / Tube Furnace(Single Zone) Specification

- Feature

- Digital temperature controller, PID auto-tuning, programmable control, corrosion-resistant structure, over-temperature protection

- Glass Size

- Tube diameter 30 mm to 150 mm (custom options available)

- Rating

- 1800C max operating temperature

- Condition

- New

- Type

- Single Zone Tube Furnace

- Usage

- Laboratory/Industrial heating applications

- Power

- 3 KW 8 KW (model dependent)

- Voltage

- 220V/230V/240V AC, 50/60 Hz

- Size

- Customized as per requirement

- Dimensions

- Dependent on tube and chamber size (e.g., outer L630 x W480 x H580 mm)

- Weight

- 5580 kg (model dependent)

- Application

- High-temperature heating, material testing, sintering, annealing

- Fuel Type

- Electric

- Capacity

- Up to 5 Liters (varies with tube size)

- Mounting Type

- Bench-top

- No. of Heating Zones

- Single Zone

- Display Type

- LED or LCD display

- Safety Features

- Over-temperature alarm, electrical leakage protection, interlock system

- Controller Type

- PID digital controller with ramp/soak setting

- Insulation

- High-purity ceramic fiber insulation

- Heating Element

- Silicon Carbide or Molybdenum Disilicide (MoSi2)

- Door Type

- Side or top loading (model specific)

- Working Tube Length

- 300 mm 1000 mm (customizable)

- Atmosphere Control

- Optional gas inlet/outlet for inert or reducing atmosphere

- Tube Material

- Quartz/Alumina/Ceramic

- Cooling Type

- Natural air cooling

- Temperature Uniformity

- 1C

- Chamber Shape

- Cylindrical/Tubular

- Temperature Range

- Room temperature to 1800C

About High Temperature / Tube Furnace(Single Zone)

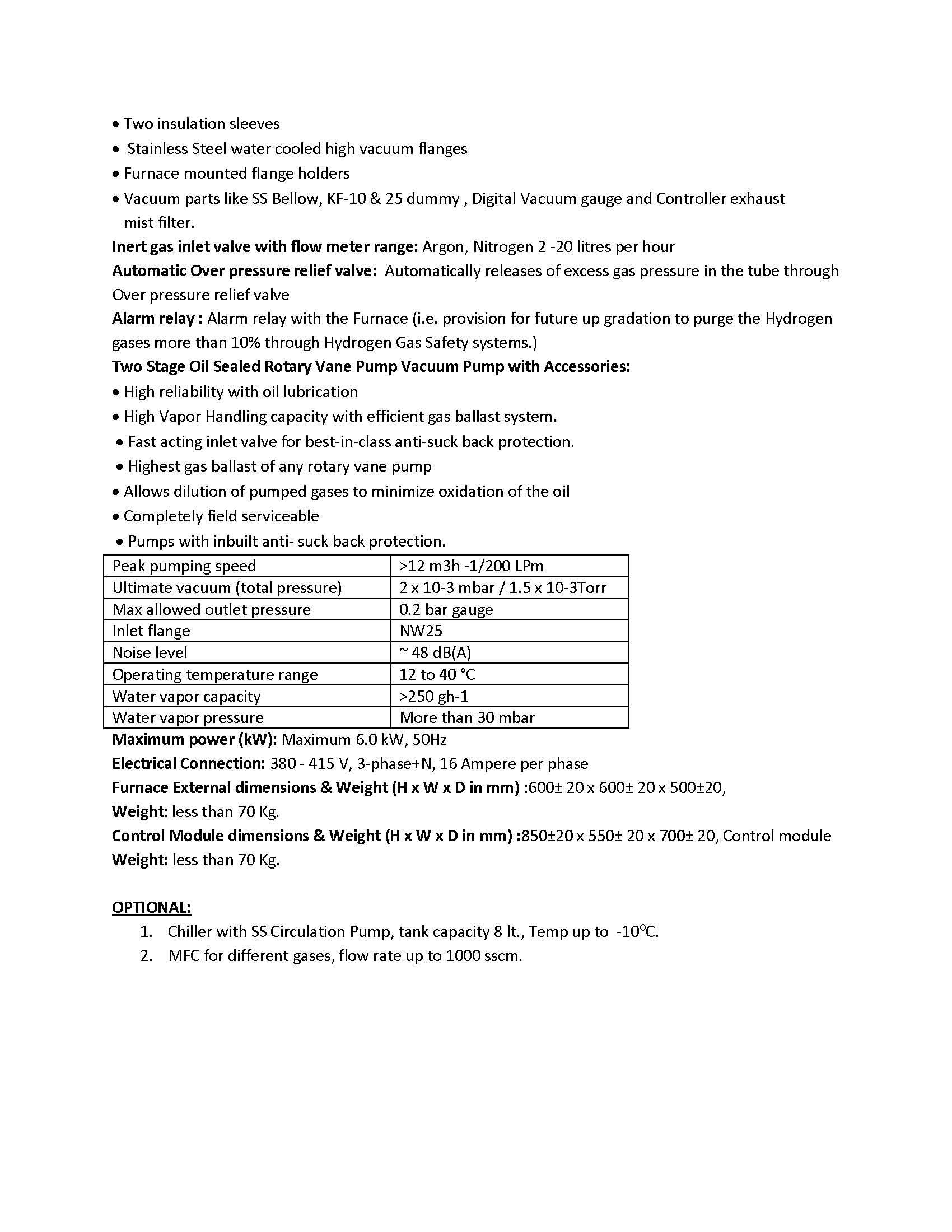

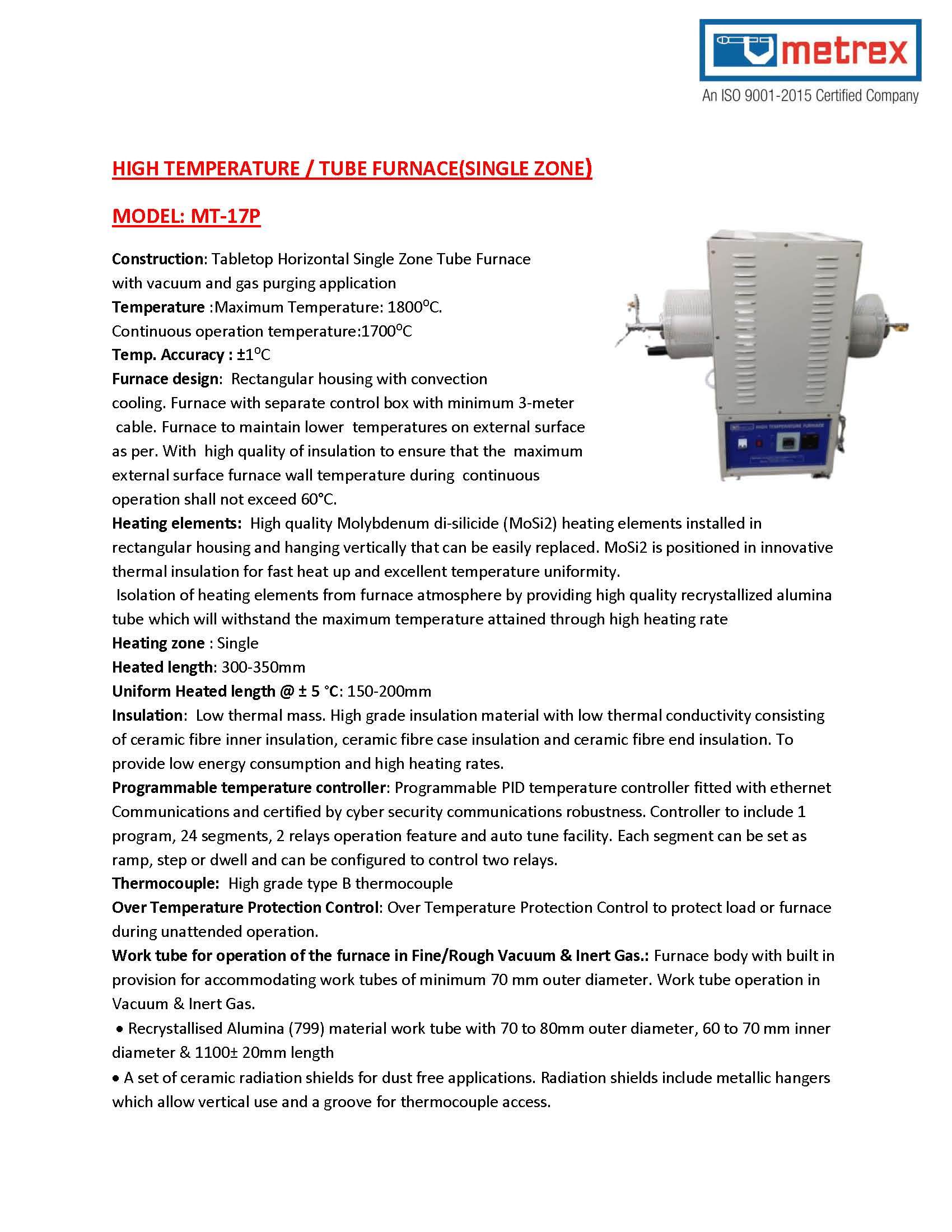

Construction:TabletopHorizontalSingleZoneTubeFurnacewithvacuumandgaspurgingapplicationTemperature :Maximum Temperature:1800 deg. C Continuous operationtemperature:1700deg.C

Temp. Accuracy : 1deg. C

Furnace design: Rectangular housing with convection

cooling. Furnace with separate control box with minimum 3-metercable. Furnace to maintain lower temperatures on external sur face as per. With high quality of insulation to ensure that the maximum external surface furnace wall temperature during continuous operation shall notexceed60C.

Heating elements: High quality Molybdenum di-silicide (MoSi2) heating elements installed in rectangular housing and hanging vertically that can be easily replaced. MoSi2 is positioned in innovative thermal insulation for fast heat up and excellent temperature uniformity.

Isolation of heating elements from furnace atmosphere by providing high quality recrystallized aluminatubewhichwillwithstandthemaximumtemperatureattained through high heating rate

Heating zone:Single

Heated length:300-350mm

UniformHeatedlength5 C:150-200mm

Insulation:Low thermal mass. High grade insulation material with low thermal conductivity consisting of ceramic fibre inner insulation, ceramic fibre case insulation and ceramic fibre end insulation. To provide low energy consumption and high heatingrates.

Programmable temperature controller:Programmable PID temperature controller fitted with ethernet Communications and certified by cybersecurity communications robustness. Controller to include 1program, 24 segments, 2 relays operation feature and auto tune facility. Each segment can be set asramp,stepor dwell and can be configured to control two relays.

Thermocouple:High grade typeB thermocouple

Over Temperature Protection Control: Over Temperature Protection Control to protect load or furnace during unattended operation.

Maximum power(kW):Maximum6.0kW,50Hz

Electrical Connection:380-415V,3-phase+N,16Ampereperphase

Furnace External dimensions &Weight(H xWxD in mm) :600+-20x600+-20x500+-20,

Weight:lessthan70Kg.

Exceptional Temperature Uniformity

Our tube furnace delivers consistent heat distribution with a uniformity of 1C, ensuring reliable experimental and industrial outcomes. The combination of high-purity ceramic insulation and premium heating elements guarantees precise control, crucial in processes such as material synthesis, annealing, and sintering.

User-Friendly Digital Control

Equipped with a PID digital controller, the furnace allows users to program complex temperature profiles with ramp and soak settings. The intuitive LED or LCD display provides real-time monitoring, letting users conveniently adjust operational parameters and maintain tight control over critical heating cycles.

Customizable and Versatile Design

This single-zone tube furnace is designed to meet diverse requirements, offering customizable tube lengths, diameters, and mounting options. Its corrosion-resistant structure, capacity of up to 5 liters, and compatibility with quartz, alumina, or ceramic tubes enhance its adaptability for various laboratory and industrial heating tasks.

FAQ's of High Temperature / Tube Furnace(Single Zone):

Q: How does the single zone tube furnace maintain precise temperature uniformity?

A: The furnace employs high-quality silicon carbide or molybdenum disilicide heating elements and high-purity ceramic fiber insulation, enabling temperature uniformity of 1C. The PID digital controller further ensures accurate temperature control throughout the heating process.Q: What materials can be used as the furnace tube, and why are they selected?

A: The tube furnace supports quartz, alumina, or ceramic tubes, each chosen for their excellent thermal stability, chemical resistance, and compatibility with high-temperature applications and different processing atmospheres.Q: When should inert or reducing atmospheres be used with this furnace?

A: Inert or reducing atmospheres are essential when heating materials sensitive to oxidation or unwanted chemical reactions. The furnace features optional gas inlet and outlet ports, allowing users to introduce gases like nitrogen or argon during processes like sintering or annealing.Q: Where can this tube furnace be installed, and what mounting options are available?

A: Designed primarily for bench-top installation in laboratories or on-site industrial setups, the furnace comes in side or top-loading models to accommodate various workspace requirements.Q: What is the process for setting up a temperature profile using the PID controller?

A: Users can program ramp/soak temperature profiles directly through the PID controller's intuitive LED or LCD interface. This allows for precise, stepwise temperature changes according to specific experiment or process requirements.Q: How does the furnace ensure operational safety during high-temperature applications?

A: Safety is enhanced by integrated features such as over-temperature alarms, electrical leakage protection, and an interlock system, which collectively help prevent accidents and protect both users and samples.Q: What are the key benefits of using this single zone tube furnace in laboratory or industrial settings?

A: The furnace offers high accuracy, consistent performance, versatile customization options, and robust safety. Its advanced control system, flexible tube configurations, and reliable insulation make it ideal for diverse high-temperature heating, testing, and material processing tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Furnace Products Category

THREE ZONE GRADIENT SPLIT TUBULAR FURNACE

Price 4000.0 INR / Number

Minimum Order Quantity : 1 Number

Usage : Other, Laboratory, Research, Material Testing

Type : Three Zone Gradient Split Tubular Furnace

Condition : New

Fuel Type : Electric

Programmable Muffle Furnace

Usage : Heating calcination annealing purposes, Other

Type : Muffle Furnace

Condition : New

Fuel Type : Electric

Two Zone Split Type Furnace

Usage : Other, Designed for precise heating and controlled thermal processing

Type : Two Zone Split Type Furnace

Condition : New

Fuel Type : Electric

High Temperature Muffle Furnace - 1400 C (Advance)

Usage : Other, Laboratory industrial and research applications

Type : Muffle Furnace

Condition : New

Fuel Type : Electric

Products Description

|

METREX SCIENTIFIC INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |