Specification

- फ़ीचर

- Three independent heating zones with separate temperature controls, Split open design for easy tube access, Digital PID temperature controller, Over-temperature protection, Rapid cooling system

- रेटिंग

- High precision, Laboratory grade

- काँच का आकार

- Accepts different tube diameters (from 25mm to 200mm OD)

- शर्त

- टाइप करें

- Three Zone Gradient Split Tubular Furnace

- उपयोग

- पावर

- वाट (w)

- वोल्टेज

- वोल्ट (v)

- साइज

- Customizable (based on tube diameter and length)

- आयाम

- मिलीमीटर (mm)

- वज़न

- किलोग्राम (kg)

- एप्लीकेशन

- Thermal Treatment, Annealing, Sintering, Gradient Heating Experiments

- फ्यूल टाइप

- Electric

- Cooling Method

- Natural convection (optional forced fan cooling)

- Mounting

- Tabletop or stand mounted

- Maximum Temperature

- Up to 1200°C or 1500°C (depending on model specification)

- Controller Type

- Digital PID Programmable controller with ramp & soak features

- Tube Material Compatibility

- Quartz, Alumina, Stainless Steel tubes

- Safety Features

- Over-temperature protection, Door interlock switch

- Temperature Uniformity

- ±1°C between zones (with proper calibration)

- Thermocouple Type

- K or S Type

- Heating Element Material

- High-grade Kanthal or Silicon Carbide

- Ambient Operating Temperature

- 5°C to 40°C

- Heating Zones

- Three independently controlled zones

- Insulation Material

- Vacuum formed ceramic fiber/Alumina ceramic wool

- Control Interface

- LCD/LED display, Optional PC connectivity

Trade Information

- Minimum Order Quantity

- 1 Number

- डिलीवरी का समय

- महीने

- प्रमाणपत्र

- CE MARK : Medical Devices Directive 93/42/EEC, Low Voltage Directives (LVD) 2006/95/EC & Machinery Directive 2006/42/EC, Electromagnetic Compatibility Directive (EMC) 2014/30/EU & Pressure Equipment Directive (PED) 2014/68/EU and EN IEC/BSEN 61010, IEC 60601, IEC 61010-1, IEC 61010-2, EN/IEC 60529, IEC 60519-2, EN 13445 & IEC 60601-2-18 ROHS- ROHS Directive 2011/65/EU ISO- ISO 9001 : 2015

About

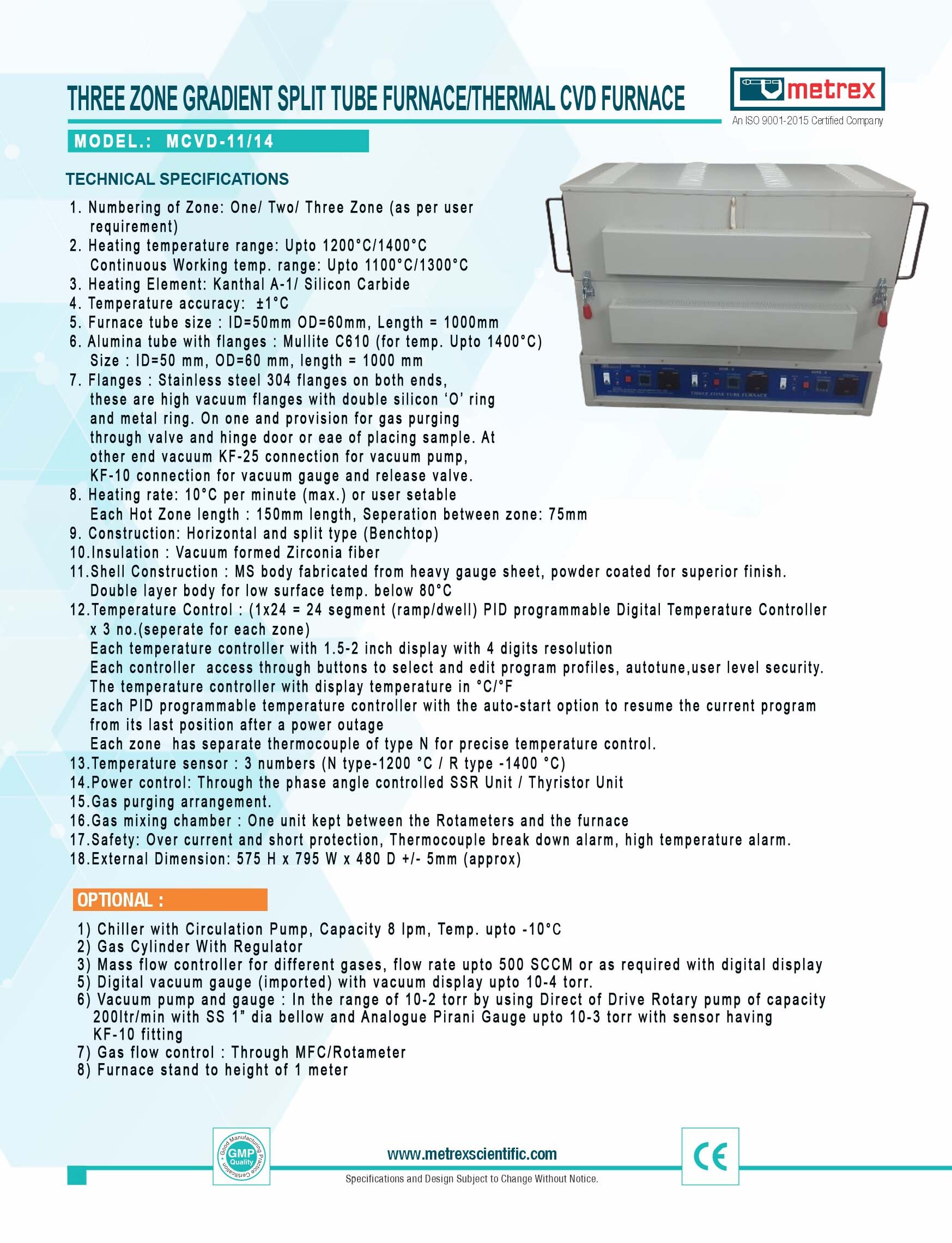

Three zone, horizontal, gradient, split typetubular furnace.Bench top model.

The furnace body is detachable from thecontroller box with at least 2 metre of cable.

The furnace is split type with hinges at therear, which will split the furnace into two halves along its length. For easyexchange of work tubes and allows the option to insert work tubes with flanges

All three zones of the furnace have a maximum operating temperature of 1200C.

All three furnace zones have continuousoperating temperature of 1100Cand usable at this temperature continuously for more than a week.

Overall heated length with minimum 600 mm ÷d into three 150 mm heated zones with two 75 mm unheated zone barriersapproximately.

Two temperature profile (gradient) graphs of thefurnace supplied along with the quote showing the temperature gradient in thefurnace for the following two temperature profiles: (1) Zone 1: 1100C Zone 2: 950C Zone 3: 800C (2) Zone 1: 1100C Zone 2: Off Zone 3: 400C.

Temperature of each zone is controlledseparately by an independent programmable PID temperature controller

Each temperature controller is one/multipleunique programs saved in memory and 24 segments which can be set as ramp ordwell.

Each temperature controller with 1.5-2 inchdisplay with 4 digits resolution

The temperature controller with displaytemperature in Celsius.

Each PID programmable temperature controllershould have the auto-start option to resume the current program from its lastposition after a power outage

Each zone has separate thermocouple of type Nfor precise temperature control.

The tubes of 50 mm ID and 60 mm OD.

2 numbers of end plugs for proper insulation ofends of the work tube.

Diameter 3 mm gland for access for optional typeN probe thermocouple up to temperature 1200C.

The furnace Kanthal A1 high-quality radiatingwire elements embedded in high-quality vacuum-formed insulation of the furnacebody, which ensures fast heat-up and excellent temperature control.

External dimensions of the furnace 575H X 795W X480D +/- 5mm.

Power consumption of furnace 2.5kW

Single Phase, 240 V, 50 Hz AC

Three-Zone Precision Heating

The split tubular furnace provides independent temperature control in three heating zones, enabling gradient temperature profiles critical for complex material research and development. Uniformity is precisely maintained within 1C, ensuring reliable results in advanced thermal treatment and experimentation. This feature is particularly valuable for laboratories carrying out gradient heating studies or simultaneous multi-sample processing.

Advanced Digital Control and Safety

A high-performance PID programmable controller regulates each zone, supporting flexible ramp and soak profiles. Its integrated over-temperature protection and interlock switches enhance safety, while the user-friendly LCD/LED display and optional PC connectivity streamline process programming and monitoring. These features combine to deliver safe, repeatable, and efficient operation during crucial research workflows.

Customizable and Versatile Design

The furnace accommodates various tube materials and diameters, making it adaptable for different research protocols. Split open construction allows convenient tube access, and mounting options include tabletop or stand. With robust insulation and a choice of cooling methods, this system meets the demands of thermal treatment, annealing, and sintering in both small-scale and higher-capacity laboratory environments.

FAQs of THREE ZONE GRADIENT SPLIT TUBULAR FURNACE:

Q: How do I operate the three independent heating zones in this tubular furnace?

A: Each heating zone is controlled separately via a digital PID programmable controller, allowing you to set and manage distinct temperatures for each zone. This flexibility is ideal for gradient heating experiments and ensures precise temperature profiles throughout the sample tube.Q: What materials can be used with the furnaces tube chamber, and how do I select the appropriate tube?

A: The furnace is compatible with quartz, alumina, and stainless steel tubes. Selection depends on your applications temperature requirements and chemical compatibility with the samples. Ensure that the tube diameter fits within the furnaces specified range of 25mm to 200mm OD.Q: When should I perform calibration for optimum temperature uniformity?

A: For best results, calibration should be conducted before initiating new experimental series, after any significant maintenance, or if you notice deviations in temperature readings. Proper calibration ensures the specified 1C uniformity between zones.Q: Where is the Three Zone Gradient Split Tubular Furnace best utilized?

A: This furnace is ideal for research laboratories, material science departments, and industrial R&D centers focused on thermal treatment, annealing, sintering, and experiments requiring controlled temperature gradients.Q: What is the process for ramp and soak programming on the PID controller?

A: The digital PID controller includes ramp and soak features, allowing you to define specific heating ramps (increase/decrease temperature at a controlled rate) followed by soak periods (maintain temperature) for each heating zone. Programming is done directly via the controllers menu or through optional PC software.Q: How does the furnace ensure user safety during operation?

A: Safety is ensured through multiple features including over-temperature protection, a door interlock switch that deactivates heaters upon opening, and robust insulation to minimize external heat exposure. These safeguards protect users and samples throughout thermal processes.Q: What are the benefits of the split open design for laboratory research?

A: The split open design allows easy insertion and removal of tubes, simplifies sample loading/unloading, and aids in rapid cooling by improving air circulation around the tube. This maximizes experimental throughput and enhances efficiency in research applications.

Price 4000.0 आईएनआर/ Number

- Minimum Order Quantity

- Delivery Time

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in फर्नेस उत्पाद Category

उच्च तापमान/ट्यूब फर्नेस (सिंगल ज़ोन)

एप्लीकेशन : Hightemperature heating, material testing, sintering, annealing

फ़ीचर : Digital temperature controller, PID autotuning, programmable control, corrosionresistant structure, overtemperature protection

उपयोग : ,

टाइप करें : Single Zone Tube Furnace

शर्त : New

माप की इकाई : यूनिट/यूनिट

तापमान और पर्यावरण नियंत्रित वैक्यूम सिंटरिंग फर्नेस

एप्लीकेशन : Controlled sintering under vacuum or inert gas atmosphere

फ़ीचर : Environment controlled vacuum sintering programmable controller with temperature ramp feature

उपयोग : ,

टाइप करें : Temperature and Environment Controlled Vacuum Sintering Furnace

शर्त : New

माप की इकाई : नंबर

मफल फर्नेस

एप्लीकेशन : Laboratory/Industrial

फ़ीचर : Compact and Efficient Design

उपयोग : ,

टाइप करें : Muffle Furnace

शर्त : New

उत्पादों का वर्णन

|

METREX SCIENTIFIC INSTRUMENTS PVT. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |